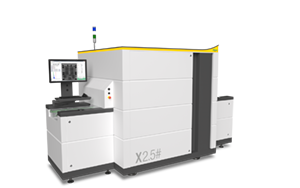

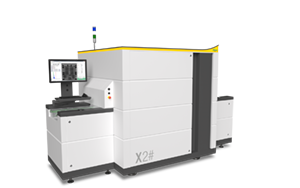

X2#

Flexible Inline

AXI system

Description

The X2# is an advanced In-line X-ray inspection system designed for high-speed automatic inspection in production lines. Transmission X-ray technology is combined with patented Slice-Filter-Technology (SFT) for double-sided PCB assembly and component inspection. The X2# features fully automatic inspection based on a CAD compiled inspection list and uses an inspection model library for the test-strategy definition. The motion system as well as the image acquisition chain meets all demands of high-speed inspection.

X-ray System Features

- Flexible Inline AXI system

- 3-axes programmable motion system with variable FOV

- Maintenace free sealed tube and digital flatpanel technology

- In-line pass through board handling with automatic width adjust

- Automatic grey-level and geometrical calibration

- Full product traceability via customized MES-Interface (incl. 1D/2D barocescan)

- Optional: Combination with MatriX AOI module

Inspection speed

Transmission (2D)

3-4 images/sec

Microfocus X-ray source (sealed)

standard:

130kV/40W

130kV/40W

optional:

100KV/20W

120kV/40W

100KV/20W

120kV/40W

Detector

standard:

CMOS Flatpanel Detector

(14 bit, 1,5k x 1,5k, 75 µm)

CMOS Flatpanel Detector

(14 bit, 1,5k x 1,5k, 75 µm)

optional:

CMOS Flatpanel Detector

(14 bit, 1k x 1k, 75 µm)

CMOS Flatpanel Detector

(14 bit, 2,3k x 2,3k, 50 µm)

TDI Line Scan

(12 bit, 2-4k, 48-96 µm)

CMOS Flatpanel Detector

(14 bit, 1k x 1k, 75 µm)

CMOS Flatpanel Detector

(14 bit, 2,3k x 2,3k, 50 µm)

TDI Line Scan

(12 bit, 2-4k, 48-96 µm)

Datasheet X2# SMT Setup

Datasheet X2# SMT Setup