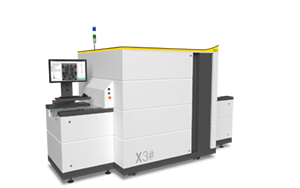

X3#

Flexible Inline

AXI system

Description

The MatriX X3# is an automated inspection system designed for sophisticated high-speed inspection in SMT production. Transmission X-ray Technology with patented Slice-Filter-Technique (SFT), Off-Axis technology and 3D SART present a reliable solution for the in-line inspection of double-sided PCB assemblies. The X3# movable detector axes allow high-speed off-axis image acquisition from different angles and directions with maximum image quality and resolution.

X-ray System Features

- Flexible Inline AXI system

- Maintenance free sealed tube and digital flatpanel technology

- Automatic grey-level and geometrical calibration

- 5 axes programmable motion

- Inline pass through board handling with automatic width adjustment

- Mixed mode inspection concept Transmission, SFT™ and selective 3D-SART

- Full product traceability via customized MES-Interface (incl. 1D/2D barcode scan)

Inspection speed

Transmission (2D)

Off-axis (2.5D)

3D SART

Off-axis (2.5D)

3D SART

4-5 images/sec

3-4 images/sec

2sec/FOV

3-4 images/sec

2sec/FOV

Microfocus X-ray source (sealed)

standard:

130kV/40W

130kV/40W

optional:

120kV/40W

150kV/75W

120kV/40W

150kV/75W

Detector

standard:

CMOS Flatpanel Detector

(14 bit, 2,3k x 2,3k, 50 µm)

CMOS Flatpanel Detector

(14 bit, 2,3k x 2,3k, 50 µm)

optional:

CMOS Flatpanel Detector

(14 bit, 1,5k x 1,5k, 75 µm)

CMOS Flatpanel Detector

(14 bit, 1,5k x 1,5k, 75 µm)

Datasheet X3# SMT Setup

Datasheet X3# SMT Setup