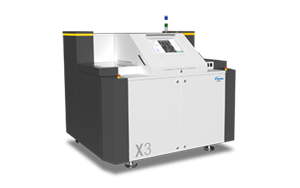

X3 S

High Speed Inline

AXI system

Description

The MatriX X3-S is an automatic X-ray inspection system featuring combined Transmission and 3D-Technology for sophisticated high-speed inspection in electronic production. The system is based on the MatriX X2.5 AXI system platform but is equipped with an additional detector axis used to generate the angle-shot images for the 3D reconstruction. This newly developed 3D reconstruction software generates high resolution slice images for 3D analysis of solder joints. Main applications are double-sided boards with critical overlapping areas.

X-ray System Features

- High Speed Inline AXI system

- Maintenance free sealed X-ray tube and digital detector technology

- 5 axes programmable motion

- Component in-tray handling setup (with automatic top clamp for parts)

- Inline pass-trough or dual lane in/out setup

- Automatic grey-level and geometrical calibration

- Full product traceability via customized MES-Interface

- Mixed inspection mode (transmission and dynamic 3D sart)

Inspection speed

Transmission (2D)

Off-axis (2.5D)

3D SART

Off-axis (2.5D)

3D SART

4-5 images/sec

3-4 images/sec

1 s /FOV (dynamic 3D mode)

3-4 images/sec

1 s /FOV (dynamic 3D mode)

Microfocus X-ray source (sealed)

standard:

130kV/40W

130kV/40W

optional:

120kV/40W

120kV/40W

Detector

standard:

CMOS Flatpanel Detector

(14 bit, 1k x 1k, 75 µm)

CMOS Flatpanel Detector

(14 bit, 1k x 1k, 75 µm)

optional:

CMOS Flatpanel Detector

(14 bit, 1,5k x 1,5k, 75 µm)

CMOS Flatpanel Detector

(14 bit, 2,3k x 2,3k, 50 µm)

CMOS Flatpanel Detector

(14 bit, 1,5k x 1,5k, 75 µm)

CMOS Flatpanel Detector

(14 bit, 2,3k x 2,3k, 50 µm)

Datasheet X3S

Datasheet X3S